Sand and shape, sand and shape

There isn’t as much to report on this week because almost all our time has been dedicated to repairing the boat. We now have a monstrous hole in our starboard forward hull! You can see into Owen’s cabin AND the starboard bow locker, at the same time, from the outside. I will try to detail what we have done for the repair.

Kevin spent a great deal of time trying determining the amount of damange and smoothing out the outside hull to be used as a form to create a mold from. While he was doing this, I continued to dismantled Owen’s cabin, including the shelving, his bed and the damaged bulkhead. It took a lot of time and the use of a reciprocating saw! Ultimately, the damage to the hull went far beyond the dent in the hull and the obvious cracks. The more damaging part of the accident was the internal delamination of the fibreglass that makes up the hull. It might look like it is in one piece, but the layers that make up the hull are actually parted inside and no longer have the same strength. In the end, we had to cut a hole that was 4m long by 1.5m high!

Getting it out was a quite the job. It turns out a piece of hull this large, is actually pretty heavy! Kevin was hoping it would be light and we could just guide it slowly down with the four of us (Kevin, Owen, Halyna and myself) but this was not the case. Not only was it too heavy, but it decided to slip as it was coming out and wedge itself partly in and partly out of the hole. It took the use of the gennaker halyard to help manipulate it out of the hole and lower it to the ground. Once on the ground, the four of us were able to carry it over to some blocks. It was a very long day by the end. We covered up the hole with a large plastic sheet and some gorilla tape.

The following week (yes, week) Kevin proceeded to apply more Bondo (a polyester filler) to the dent, in successive layers, until the hull was the same shape as the other side. Each layer required time to dry and then be sanded in between. Kevin is forever frustrated with the Bondo because it dries in about 3 minutes (despite putting minimal drying agent into it) and doesn’t allow him adequate time to spread it out before he needs to make more. Therefore, he makes it in small batches. However, the Bondo then takes several hours to dry enough to sand. We took templates of the side profile from the port hull to help us develop the same shape on the damaged hull piece.

While Kevin is sanding and shaping, Owen has drained water from the inside of our dinghy. Turns out there is a condensation plug, that plugs the space between the hull of the dinghy and the deck inside. We met some people in Georgetown that said they knew somebody with our boat who opened that plug and got some water out. So, we decided to try the same. The small hatch in the bow of our dinghy is always flooding with water that seems to come from that space. Also, our boat is so heavy and we would do anything to make it lighter. We noticed a plug in this space previously, but it is a wooden plug. It is supposed to be a plastic plug that can screw out, presumably to allow condensation out every once in a while. Instead, somebody had previously fill it will a wooden plug/wedge and then added a screw in the middle to helped it expand. However, it meant it wasn’t easy to get out and some water would seep in around it. It took Owen the better part of 2 days to chip out the wooden plug and screw. Then, when he finally got it out, tons of water poured out! I am sure that the full space was full of water. We will put in the proper plastic plug and are excited to have a much lighter dinghy! Halyna made the dinghy even better by cleaning it inside and out.

Also done while Kevin was sanding and shaping, Owen and I cleaned the propellers of our bowthrusters. They were fully clogged up with barnacles. Barnacles smell very badly when they are scrapped off if they have any moisture left in them. So it is a somewhat unpleasant tasks. We also spent several days trying to actually take the propellers off so that we could ensure it was fully cleaned, but it would not budge despite all our efforts. We tried tugging it off with the use of webbing and a hammer but, no go. In the end, they are as clean as we could get them and we replaced the zincs.

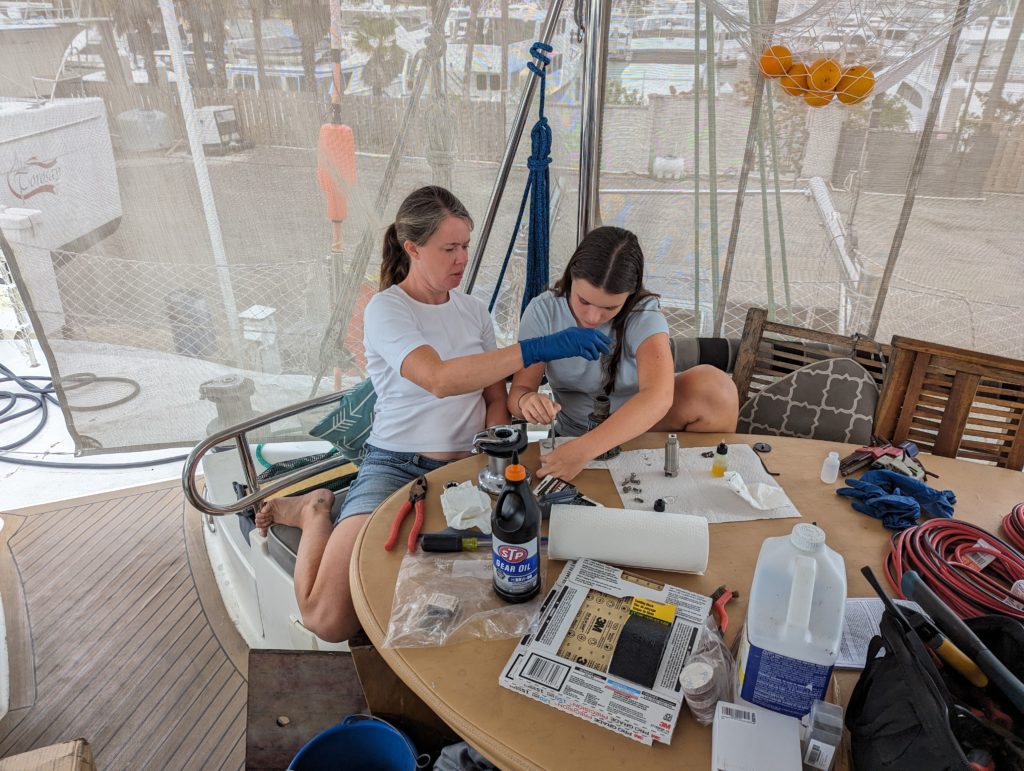

Finally, Halyna and I have been working on taking apart, cleaning, and rebuilding more of our winches. We last did this in Newport but only got to 2 of our 8 winches done. It is tricky because we have to remember how to put all the gears back together in the same place and order. The little kids had to stop scootering around the boatyard because some other boat owners felt that they shouldn’t be scooting too close to their hulls or potentially near the boat lift. So, they have now resorted to reading and using walkie-talkies to pass messages to each other. When they are really bored, they listen to the weather report. They have been very patient with all the time in the now dull boatyard.

Outside the boatyard, we had to move to a new Airbnb for a week. It is slightly larger and has a ping pong table for the kids to play with. I really liked seeing them playing all together every evening when we were there. Kevin and I continue to enjoy running more, which also helps with the stress of doing a repair, and allows us a chance to explore the neighbourhood a little. Finally, one day we took the day off and drove to Orlando to see what we could see. No, we did not go to the theme parks, but we did check out the area near Universal Studios and do some people watching. It was a nice break.

Kevin says the hull piece is finally in the shape he wants and smooth enough to make the mold! So, tomorrow we will be applying several layers of a waxy release agent before using fiberglass to build the mold.

3 Comments

Keely Kastrukoff

You are all working so hard! It’s impressive how much you have all accomplished with fixing the boat. Glad you have time for the Taco Trucks! I love the sunset photo 🙂

Monica G.

I’m absolutely amazed at the knowledge you have on how to repair a sailboat and dinghy.

It must be a difficult task and managing the heavy lifting you are doing. Even though it’s very difficult work, I’m sure it’s very rewarding to see what your family is accomplishing together. The memories and stories you will all share throughout your lifetimes will be forever never ending. I’m sure you will be back on the water in no time. For now, take care and have a fantastic Easter. I’m looking forward to hear more about your upcoming accomplishments. 🐣⛵️ Monica

Jennie

Thanks Monica for the support!

Happy Easter to you too.